Weld Overlay Clad Process

RocCLAD is a metallurgical bonding technology of two kinds of different metals. It is the 100% metal fusion technique.

RocClad makes overlay welding on most carbon, low alloy, chrome moly, stainless steel and other steels with variety of corrosion resistant alloy including Inconel®, Incoloy®, Monel®, Hastelloy®, stainless steel and hard facing materials. Benefiting from our advanced DSP or PLC controlled welding stations and optimized producing process, we offer low dilution of alloy deposit. Real time video monitoring and recording system ensure perfect tie in and weldpath. Iron (Fe) content of the Inconel 625 cladding layer can reach less than 5% in the surface 1mm below the top surface.

HRB Clad Fitting Process

RocCLAD CRA clad pipe fittings are made of weld overlay clad pipes or clad steel plates, pipe/plate forming, automatic welding equipment, 100% RT after welding, pickling&passivation, and bevelling process are adopted to ensure a high degree of automation in the whole process. The types of products are elbows, tees, reducers, caps, etc. The diameter range of welded pipe can be 16”~80”, wall thickness 9.27mm~90mm.

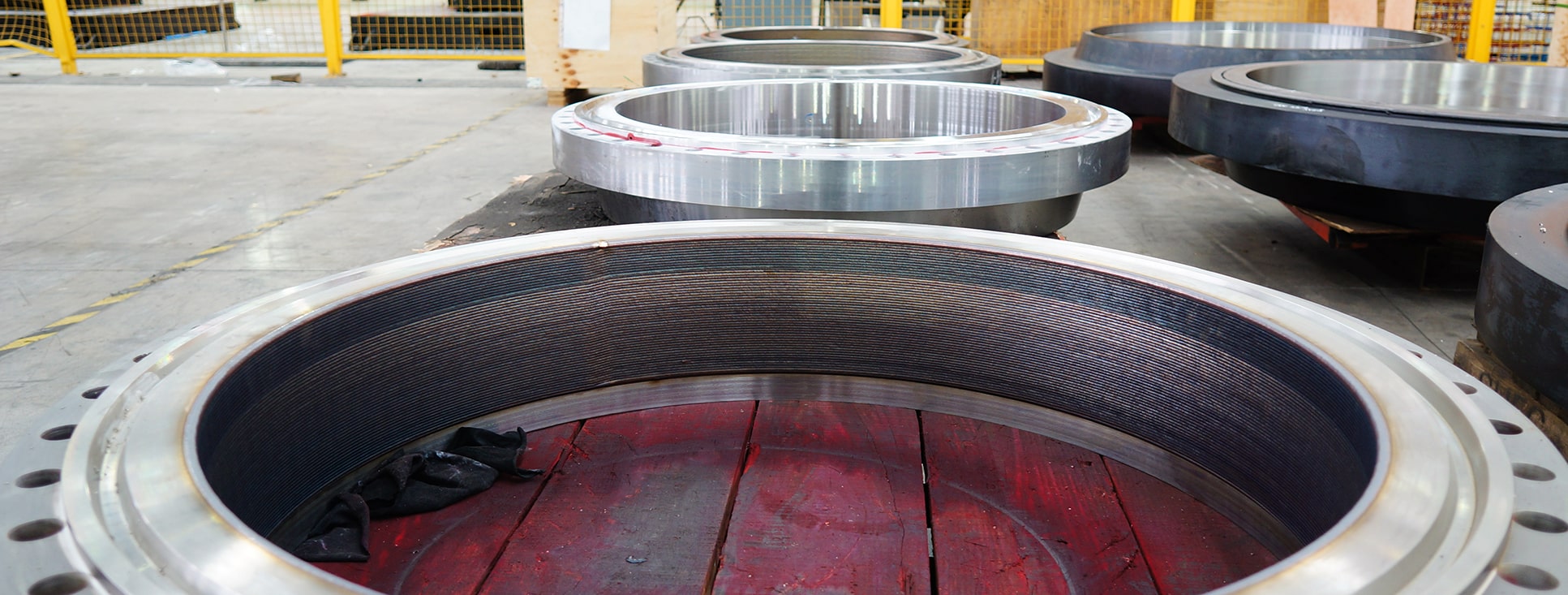

Clad Valves, Flanges, Forgings and Fittings

- Bore: 30mm~1800mm

- Base Material of Valves: ASTM A216 WCB, WCC; A352 LCC...

- Base Materials for Flange and Forgings:

ASTM A105/A105N, ASTM A350 LF2 CL2, LF6 CL2

ASTM A694 F42, F52, F60, F65, F70

ASTM A182 F304/304L, F316/316L

API 45K, 60K, 75K

AISI 4130 (M), 4140, 4340, 8630(M) - Base Materials for Pipe Fittings:

ASTM A234 Grade WPB, WPC, WP11, WP22

ASTM A860 WPHY52, WPHY60, WPHY65, WPHY70

ASTM A420 WPL6

ASTM A516 GR. 60/GR. 70 - Others