What is Weld Overlay?

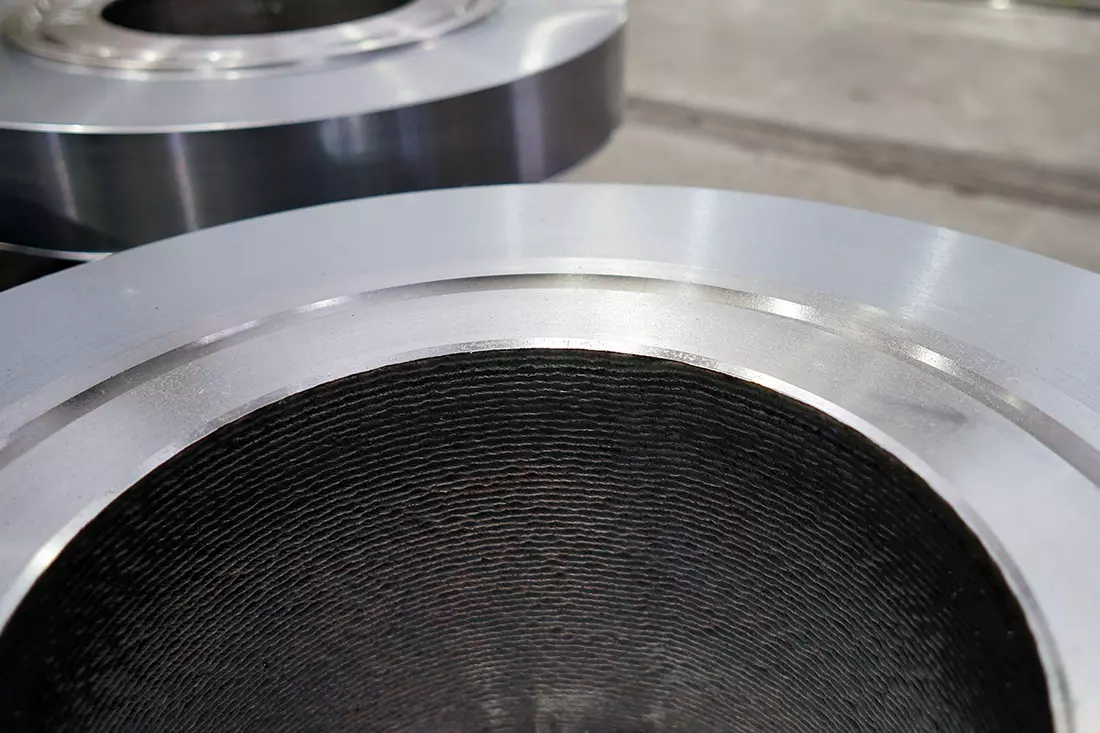

RocCLAD is a metallurgical bonding technology of two kinds of different metals. It is the 100% metal fusion technique. RocCLAD makes overlay welding on most carbon, low alloy, chrome moly, stainless steel and other steels with variety of corrosion resistant alloy including Inconel®, Incoloy®, Monel®, Hastelloy®, stainless steel and hard facing materials.

Benefiting from our advanced DSP or PLC controlled welding stations and optimized producing process, we offer very low dilution of alloy deposite. Real time video monitoring and recording system ensure perfect tie in and weld path. Iron (Fe) content of the Inconel 625 cladding layer can reach less than 5% in the surface 1 mm below the top surface with minimum 3mm total layer thickness.

The CRA layer will be achieved by weld overlay, so that our customers will obtain better anticorrosion and wear resisting property at a lower cost thereby extend the service life of piping system.

RocCLAD has been widely applied on hot induction clad bends for the long-distance transport pipeline, risers for the offshore platform, piping products for the submarine special equipments, stations, X-tree well head, DD EE FF HH grade X-trees parts, well-head valves, Hydrogenation reactors and so on, while mechanical lining method has hardly used in such working conditions.

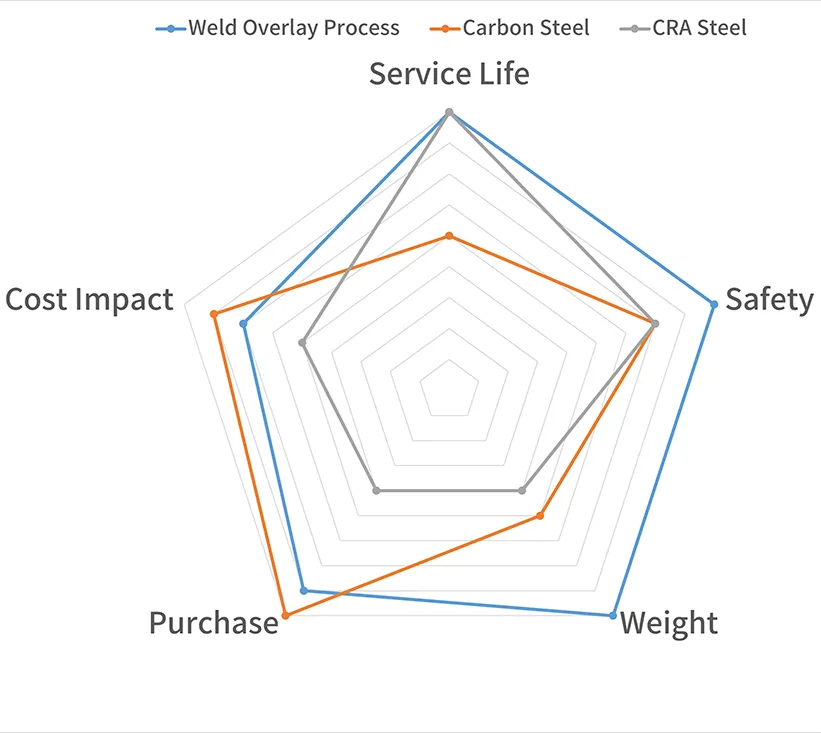

Advantages of cladding welding process

Weld Overlay Process | Carbon Steel | CRA Steel | |

|---|---|---|---|

Service Life | Longeryes | Shorter | Longeryes |

Safety | Anti Corrosion + | High Mechanical Property | Anti Corrosion |

Weight | No Additional Corrosion | Additional Corrosion | Heavier, due to lower |

Purchase | Welding Wire in Stock | Easy to Purchaseyes | Hard to Purchase and |

Cost Impact | If you consider | Low Costyes | Expensive |

Roc-Master's weld overlay technology

Roc-Master is a well-known corrosion-resistant alloy cladding expert and a manufacturer that can provide forgings and cladding, and can provide customers with overall solutions for corrosion-resistant pipeline products. Our core technology is the application of internationally advanced corrosion-resistant alloys and the continuous development of weld overlay technology.

Roc-master's weld overlay technology has been maturely applied in many projects in severe corrosion, abrasion, and cavitation environments around the world. Roc-Master's weld overlay technology establishes an anti-corrosion alloy layer inside pipelines and pipeline accessories or equipment, containers, etc. to protect the overall pipeline and facility application system, providing customers with low-cost and long-term solutions in extremely harsh environments such as corrosion resistance, abrasion, and cavitation.

RocClad Overlay Welding Process

The RocCLAD overlay welding process is a metallurgical composite of two dissimilar metals, achieving 100% metallic fusion.

RocCLAD can apply stainless steel and various corrosion-resistant alloys, including Inconel®, Incoloy®, Monel®, Hastelloy® alloys, and hard-facing steels, onto most carbon steels, low-alloy steels, and chromium-molybdenum steel substrates. Advanced DSP or PLC-controlled automated welding workstations, optimized production processes, and real-time video monitoring systems enable the delivery of low dilution rate alloy layers and perfect welding bonds. For example, the Fe content of the Inconel 625 overlay can be maintained below 5% at a depth of 1mm beneath the surface.

The corrosion-resistant alloy layer can be applied via overlay welding, pipe lining, or explosive bonding. The overlay welding process offers stronger corrosion and wear resistance at a lower cost, significantly extending the service life of pipeline systems.

The RocCLAD overlay welding process has been widely applied in:

- Bends of long-distance pipelines in engineering projects

- Risers for offshore oil platforms and subsea special equipment

- Stations, wellhead instrument measurement short pipes, field openings, DD/EE/FF/HH-grade Christmas tree components, wellhead valves, and hydrogen reactors.

- In these scenarios, lining processes are nearly impractical.

RocCLAD Overlay Welding Capacity

RocCLAD possesses over 61 computer-controlled, programmable track automatic welding machines and integrated automatic welding systems, including 17 fully automatic pipeline overlay welding machines and 44 horizontal/vertical automatic welding machines. The annual welding wire capacity reaches 580 tons.

RocCLAD maintains long-term safety stock of imported welding wires:

- Incoloy®825: 10 tons

- Inconel®625: 20 tons

- Domestic 316-grade welding wire: 3 tons

Additionally, RocCLAD operates a dedicated bonded warehouse for imported welding wires, ensuring consistent safety inventory of Incoloy®825 and Inconel®625 bonded welding wires to enhance competitiveness in international offshore engineering projects.

Application Scope of RocCLAD Overlay Welding Products

Subsea Applications

- Subsea Christmas trees, manifolds, pipelines, bends, anchors, flanges, valves

- Risers, bends, and elbows for offshore oil platforms

Onshore Infrastructure

- Gathering stations, processing plants, desulfurization/decarbonization units, hydrogen reactors:

- Christmas trees, bends, pipe fittings, flanges, insulated joints

- Natural gas processing plants and export stations:

- Bends, pipe fittings, flanges, valves

Pressure Vessel Components

- Branches, parts, flanges, tube seats

Specialized Industrial Systems

- Coal-to-liquid corrosion/wear-resistant pipelines, fittings, flanges, valves

- High-pressure alloy pipelines and prefabricated piping systems (e.g., duplex/super duplex steels, nickel alloys)

Welding Types of RocCLAD

GTAW (TIG) – Tungsten Inert Gas Welding

Mechanized/Manual (Hot/Cold Wire) Welding: Utilizes non-consumable tungsten electrodes under inert gas shielding (e.g., argon or helium) for high-precision welding. Suitable for stainless steel, titanium, copper alloys, and aluminum (via AC-TIG with cleaning action).

Manual FCAW (MIG) – Flux-Cored Arc Welding

A semi-automatic process using a continuously fed consumable electrode wire with flux core. Combines high deposition rates with good penetration, ideal for carbon steel and high-strength alloys.

Manual SMAW – Shielded Metal Arc Welding

A traditional stick welding method using flux-coated electrodes. Simple equipment and versatile for field applications, though slower and requiring frequent electrode changes.

Our Overlay Welding Products

Pipes and Piping Systems

- Pipes, pipe fittings, prefabricated piping systems

- Flanges, blind flanges, tube seats, forged nozzles, iron blocks, tees

Valve Components

- Valve bodies, spheres, bonnets, seats, and other valve elements

Risers and Flowline Components

- Risers, flowlines, and pipeline accessories

Heat Exchanger Components

- Heat exchanger shells and tube sheets

Drilling Equipment

- Wear-resistant overlay welding on stabilizer wear surfaces and other drilling equipment