R&D of RocLok Clamp Hub Connector has been initiated since 2013. Over 7000 sets of RocLok products have been successfully supplied to FPSO projects in the past 10 years ever since 1st dispatch to SBM.

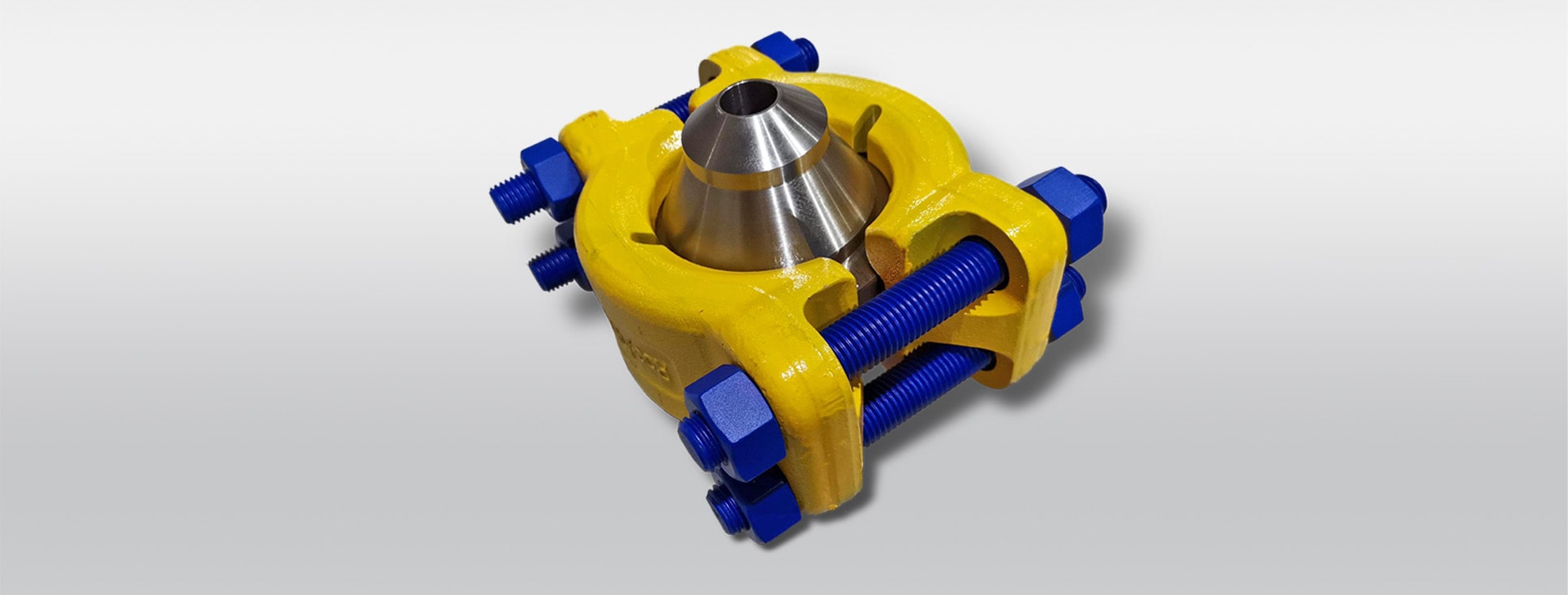

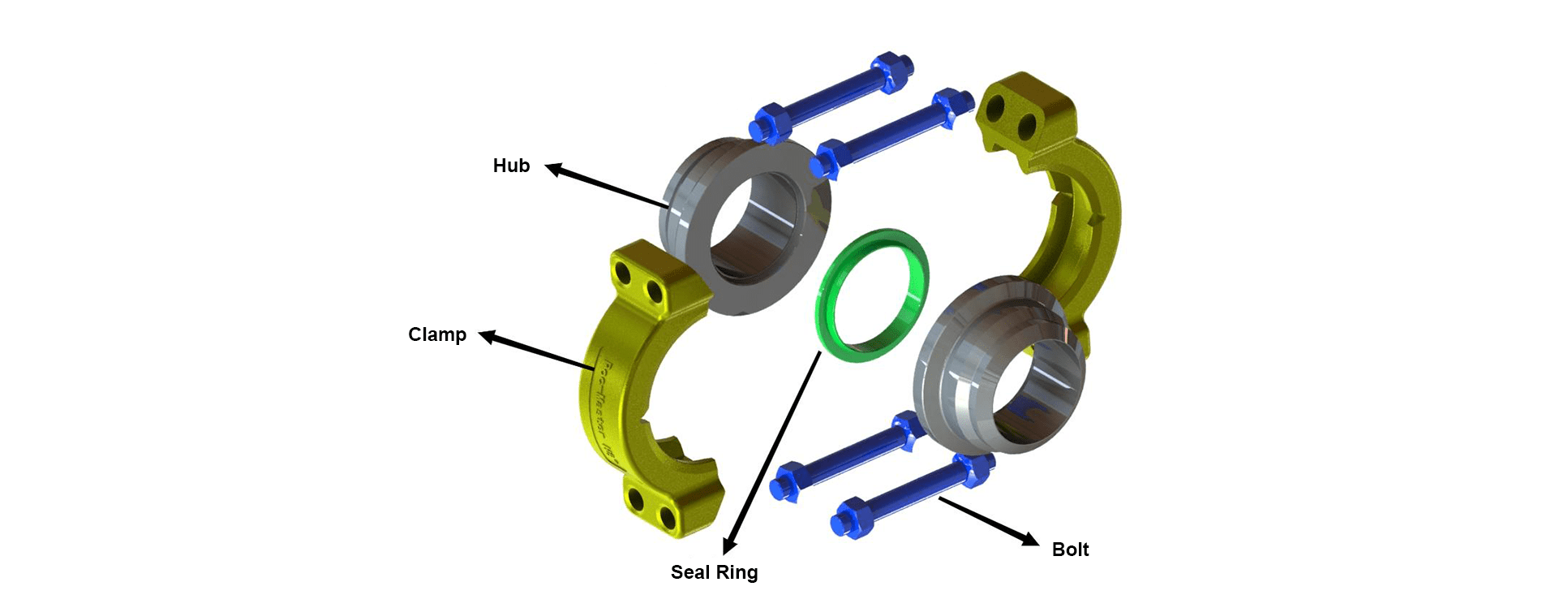

Clamp hub connector, is a commonly used pipeline connection with advantage of easy installation. It also has other features such as 75% weight reduction compared with ANSI and API flanges, size reduction, and high pressure bearing. With only 4 sets of bolts, the hub can be rotated 360 degrees without aligning the bolt holes as in the case of conventional flanges. During operation, the clamp hub connector can maintain internal pressure, bending & axial loads simultaneously and can ensure free leakage of pipeline, well assembly of bolting which is a cost-effective and environment friendly connection solution.

RocLok unique sealing technology-based clamp hub connector has acquired 11 patents since 2016. Roc- Master Engineering Technology Center performs design, FEA (Finite Element Analysis), test verification, etc. according to project requirements to ensure product reliability. High-precision professional equipment such as three-coordinate meter, roughness tester, thickness tester, professional flaw detector, etc. are used for inspection. Roc-Master applies strict quality control throughout manufacturing process to ensure the high- quality of our products.

RocLok Clamp Hub Connector is independently produced in Roc-Master own facilities as per actual work flow for forging, heat treatment, machining, overlay welding, clamp PTFE coating, bolt Xylan coating, etc., including inspection & testing. Clamp size range is 1/2"~26". Availability of stocks for seal ring and bolting is an absolute advantage for fast-track projects. The overall delivery can be expected within 12 weeks and reduced to 8 weeks in case of urgency.

RocLok is interchangeable with other foreign brands such as GrayLoc, G-LOK, WireLoc, TechLok, etc. and experienced to handle installation, successful testing, and assembling with other brands at critical stage.

Moreover, Roc-Master can also provide a quick solution, such as Hub End Dummy Valve, etc.

Roc-Master technology, design, product, quality and after-sales engineers have years of practical experience in the formulation of technical specifications and on-site technical support for projects, technical services, clamp hub connector installation guidance & application. With knowledges of specifications & standards, understanding of technology, our design engineers can provide supports and technical services to valve, equipment manufacturers, etc.

Based in China, Roc-Master group has enhanced competitiveness and shortened construction period for users and construction yards by virtue of excellent quality management system, advanced manufacturing equipment guarantee, outstanding technical, management and quality talents.

Features:

RocLok Clamp Hub Connector is a lighter, more efficient and more quality-reliable product, which is mainly used in subsea and FPSO pipeline connections and equipment end connections. It is suitable for onshore drilling and mining, coal chemical equipment and line connection.

RocLok Clamp Hub Connector has the features of compact structure, light weight, easy installation, less bolting and high pressure bearing. RocLok Clamp Hub Connector is capable of withstanding considerable bending moments and axial force under pressure without leaking or bolt loosening, which greatly reduces maintenance costs and optimizes space resources.

High-strength sealing material promotes the reuse of the seal ring. The double-cone structure pressure self-tightening metal sealing technology is one of the core technologies of Roc-Master.

Nickel-based alloy weld overlay can be used in the sealing area to improve the corrosion resistance of the sealing material. The specialized surface treatment at a maximum pressure of 15000psi(103.5Mpa) improves corrosion resistance while reducing the coefficient of friction, guaranteeing viable connections and seals.

The Type Approval Certificate has been issued by DNV.

The Manufacturer standard has been issued, and the standard number is Q/320583RMYJ006-2013.

RocLok is interchangeable with other foreign brands such as GrayLoc, G-LOK, WireLoc, TechLok, etc.

Services:

Our products are available in the market with supply reference of SOFEC, Technip, YINSON, MODEC, SBM, PETROBRAS, BP, WOODSIDE, etc.

Design Standard:

ASME B31.3, ASME VIII Div.1, Div.2 or Div.3, API 6A, DNVGL-RP-D101,

DNVGL-CP-0185, NACE MR0175/ISO 15156

Material:

Hub material:

- A105, A350 LF2, LF3, LF6, A522 Type 1 or with Inconel 625 weld overlay

- A694 F42/F52/F60/F65/F70/F80 or with Inconel 625 weld overlay

- A707 L3 Cl.2/Cl.3, A707 L5 Cl.3, A859 CL.2

- AISI 4130/4140

- A812 F1/F5/F5a/F6a/F9/F11/F22/F22V/F91/FXM-19

- A182 F304/F316/F904L/F321/F347/F44/F49/F51/F53/F55/F60

- Nickel alloy

Clamp material (including bolting):

- AISI 4130/4140-B7/2H, L7/7, L7M/7M

- A182 F304/F316/F321/F347-B8/8

Seal ring material:

- AISI 4130/4140

- A182 F304/F316/F51/F53/F55/F60

- ASTM B637 UNS N07718

- A564 GR.630

Dimension and Rating:

- 0.5"~26" CL150~CL2500

- 0.5"~26" API 2000psi~10000psi

- 0.5"~18" API 2000psi~15000psi