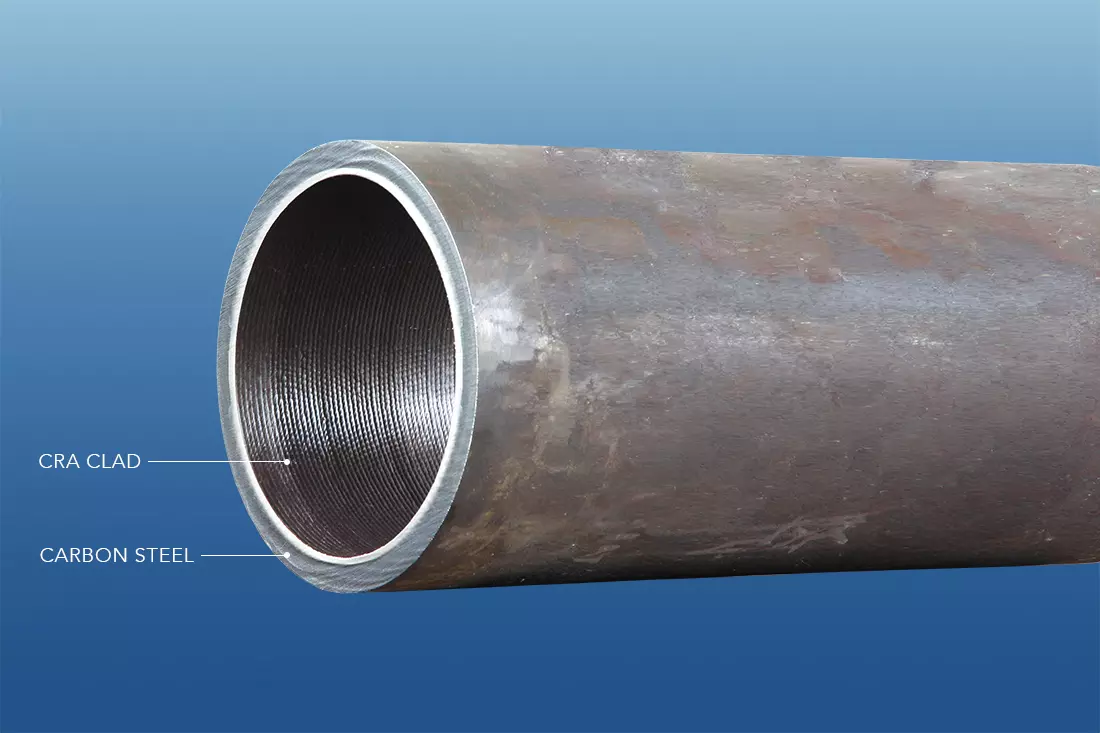

Weld Overlay Clad Process

RocCLAD is a metallurgical bonding technology of two kinds of different metals. It is the 100% metal fusion technique.

RocClad makes overlay welding on most carbon, low alloy, chrome moly, stainless steel and other steels with variety of corrosion resistant alloy including Inconel®, Incoloy®, Monel®, Hastelloy®, stainless steel and hard facing materials. Benefiting from our advanced DSP or PLC controlled welding stations and optimized producing process, we offer low dilution of alloy deposit. Real time video monitoring and recording system ensure perfect tie in and weldpath. Iron (Fe) content of the Inconel 625 cladding layer can reach less than 5% in the surface 1mm below the top surface.

Seamless & Welded CRA Clad Pipes

- Base Material of Pipes: ASTM A53 Gr.B, A106 Gr.B, API 5L Gr.B, X42, X52, X60, X65, X70; ASTM A333 GR.6, Stainless Steel

- API 5L+CLAD, A671 / A672 + CLAD

- ID Ø110~1200mm; Length up to 12.2 m

- CNC boring & milling machine bevel processing

- Automatic internal and external joint welding

- Pipe end laser measurement

- Pickling and passivation on internal surface

- 3LPP anti-corrosion protection on pipes outside surface

- Thickness of base pipes: 6mm~75mm

- Process of Bending: Hot Induction Bending and Cold Bending

- Bend Radius: 3D~10D or on customer’s request

- Bend Angles: For Cold Bending 1°~180° / For Hot Induction 1°~100°

- Diameter of Clad Bends: 4”~24”

- Wall Thickness of Clad Bends: STD~75mm

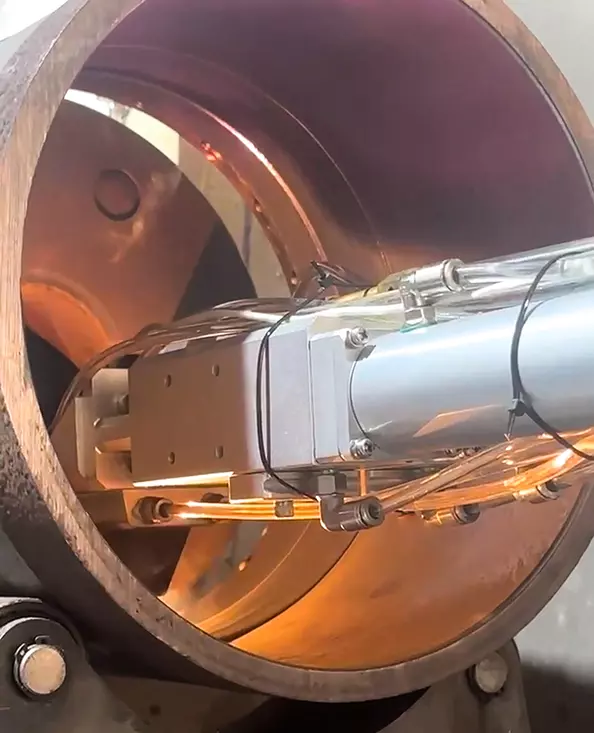

Laser Cladding Pipe

In the field of pipe cladding, Roc-Master leverages advanced laser cladding technology, utilizing a high-energy-density laser beam as the heat source. By precisely delivering filler material through wire or powder feeding, a fully molten pool is generated and meticulously applied to the inner surface of the pipe. This process creates a corrosion-resistant cladding layer that dramatically enhances surface performance, providing protection and durability far beyond that of the base material.

Technical Parameters:

Technical Parameters:

Base Material of Pipes: API 5L X60/X65/X70, A106 Gr.B, A333 Gr.6, etc.

Cladding Material: N06625, N08825, SS316L, 2209, etc.

Wall Thickness ≥ 6mm

Length: Up to 12.5m

Laser Cladding Wire: Inner Diameter ≥ 220mm, Cladding Layer Thickness ≥ 0.8mm, Efficiency ≥ 4kg/h

Laser Cladding Powder: Inner Diameter ≥ 70mm, Cladding Layer Thickness ≥ 0.5mm, Efficiency ≥ 3kg/h

Applications

- Seawater Engineering: Seawater lifting and transportation, seawater desalination treatment

- Oil and Gas Development: Drilling, completion, transportation, process wastewater

- New Energy: Geothermal lithium and nickel extraction for battery preparation

- Energy Storage: Compressed air energy storage in underground salt caverns

- Nuclear Energy: Nuclear wastewater treatment